Glass & Aggregates

We pride ourselves in understanding the ins and outs of the glass/aggregates industry from working with some of the top manufacturers in the country (and also have our corporate headquarters next to one, Hi – NSG Pilkington). Processes such as bulk material handing, melting, processing or forming, and product distribution – from the equipment acquisition stage to the final installation, let IPS partner with you! Our comprehensive services have let us to projects like:

- Batch Houses

- Dust Collection Systems

- Crushing & Pulverizing Systems

- Furnaces & Melters

- Float Lines, Fiberglass, Tableware, & Specialty Glass Systems

- Material Handling, Conveyance Systems, & Bucket Elevators

With our advanced Virtual Design & Construction, our team can merge any existing process with a value-added upgrade or addition at your current facility utilizing our 3D laser scanning.

Related Services

Projects

NSG Pilkington – Furnace Rebuild

Furnace Rebuild NSG Pilkington – Rossford, Ohio Pilkington announced their plans to rebuild their 6F1 and 6F3 furnaces at the

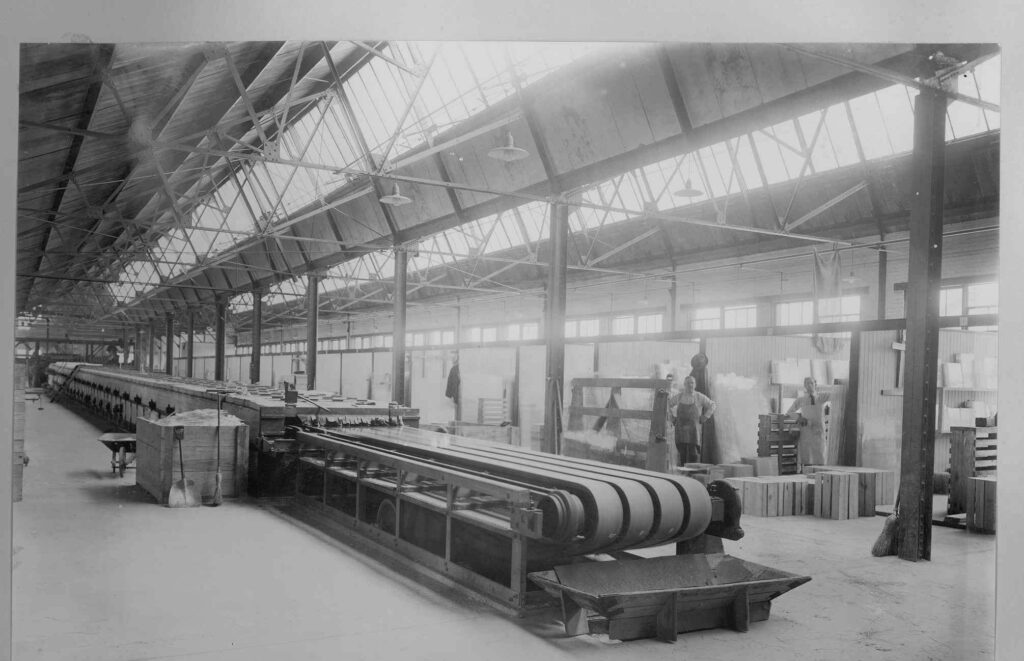

Libbey Glass – Production Line Relocation

Production Line Relocation Libbey Glass – Shreveport, Louisiana to Toledo, Ohio IPS relocated and reinstalled the BLT (Black Label Tableware)